User:Davidbbell3/Silver mining

Silver mining is the resource extraction of silver by mining.

Silver is found in a native form very rarely as nuggets, but more usually combined with sulfur, arsenic, antimony, or chlorine and in various ores such as argentite (Ag2S), chlorargyrite ("horn silver," AgCl), and galena (a lead ore often containing significant amounts of silver)[1][2]. As silver is often found in conjunction with these or alloyed with other metals such as gold, it usually must be further extracted through amalgamation or electrolysis.

Silver mining has been undertaken since early times. As silver is a precious metal often used for coins and bullion, its mining has historically often been lucrative. As with other precious metals such as gold or platinum, newly discovered deposits of silver ore have sparked silver rushes of miners seeking their fortunes. In recent centuries, large deposits were discovered and mined in the Americas, influencing the growth and development of Mexico, Andean countries such as Bolivia, Chile, and Peru, as well as Canada and the United States.

History

[edit]

Silver has been known since ancient times. Silver is mentioned in the Book of Genesis, and slag heaps found in Asia Minor and on the islands of the Aegean Sea indicate that silver was being separated from lead as early as the 4th millennium BC. The silver mines at Laurium were very rich and helped provide a currency for the economy of ancient Athens, where the process involved mining the ore in underground galleries, washing and then smelting it to produce the metal. Elaborate washing tables still exist at the site which used rain water held in cisterns and collected during the winter months.[citation needed]

The Roman took over silver mining in Spain from Carthage after their acquisition of Carthaginian territories there following the Second Punic War. Extraction of silver from lead ore was widespread in Roman Britain very soon after the Roman conquest of the first century AD.

From the mid-15th century silver began to be extracted from copper ores in massive quantities using the liquation process creating a boost to the mining and metallurgy industries of Central Europe.

Americas

[edit]

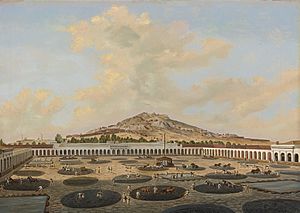

Vast amounts of silver were brought into the possession of the crowns of Europe after the conquest of the Americas from the now Mexican state of Zacatecas (discovered in 1546)[3] and Potosí (Bolivia, also discovered in 1546), which triggered a period of inflation in Europe. Silver mining required large amounts of mercury to extract the metal from ore. In the Andes, the source was the Huancavelica mercury mine; Mexico was dependent on mercury from the Almadén mercury mine in Spain. Mercury had a very high and adverse environmental impact.[4] Silver was extremely valuable in China, became a global commodity, contributing to the rise of the Spanish Empire. The rise and fall of its value affected the world market.

In the first half of the 19th century Chilean mining revived due to a silver rush in the Norte Chico region, leading to an increased presence of Chileans in the Atacama desert and a shift away from an agriculture based economy.

Silver mining was a driving force in the settlement of western North America,[5] with major booms for silver and associated minerals (lead, mostly) in the galena ore silver is most commonly found in. Notable silver rushes were in Colorado; Nevada; Cobalt, Ontario; California and the Kootenay region of British Columbia; notably in the Boundary and "Silvery" Slocan. The first major silver ore deposits in the United States were discovered at the Comstock Lode in Virginia City, Nevada, in 1859.

Silver Ores

[edit]

Silver-bearing ore typically contains very little silver, with much higher percentages of copper and lead. As such, most silver produced is refined from sulfide ores such as galena (lead) or chalcopyrite (copper) which contain small amounts of silver [6]. Many of these ores are mined for their value as sulfide ores, and silver is extracted as a valuable by-product, however, some ores are mined explicitly for their silver value[7]. Flotation separation is a key step in this complicated process. Silver mineralizes most commonly as argentite, polybasite and proustite, Ag2S, (Ag, Cu)16Sb2S11 and Ag3AsS3 respectively [8]

Methods for mining silver vary between mines depending on factors related to the ore body, such as the grade of the ore, its depth, host rock, and economic factors. Commonly, silver is extracted in open pit mines, and underground drifts and shafts[9]. One of the most challenging aspects of silver mining is extraction of the ore, as silver and its host rock can be very heavy. Explosives are frequently used to shatter veins into manageable pieces, which are transported via mine cars and then lifted to the surface[9][7].

In recent history, there have been global silver deficits as a result of greater demand than supply. To combat this silver scrap mining became more prevalent. A significant amount of silver can harvested from scrap materials, 1,700 tons were recovered in the United States in the year 2000[9]. Silver scrap has a much lower value than other metals, and as a result of this traditional techniques that work for many materials do not work for silver. Jewelry is commonly re-alloyed as opposed to being refined, although this silver is less pure. The same process is undertaken for recovering silver from dental alloys and silverware. Photographic film is another source of economic scrap, as silver can be extracted from spent film via leaching of burnt film ashes. [9]

Ore processing

[edit]

Once silver ore has been removed from a mine, it is crushed into a fine powder. Silver is commonly extracted from the powdered ore by smelting or chemical leaching. Silver’s melting point occurs at 962oC (1764oC, 1,235.15K). As such, industrial metallurgic processes are needed to prepare silver for commercial purposes.[10] Ore treatment by mercury amalgamation, such as in the patio process or pan amalgamation was widely used through the 1800s, but is seldom used today[9].

Parting is a common process by which metallic silver can be extracted. This is done by dissolving a gold alloy (less than 30% gold) and boiling with 30% nitric acid. Affination is the process of boiling silver and gold with concentrated sulfuric acid[6]. This separates the silver and gold.

Silver is also produced during the electrolytic refining of copper and by application of the Parkes process on lead metal obtained from lead ores that contain small amounts of silver. Commercial grade fine silver is at least 99.9 percent pure silver and purities greater than 99.999 percent are available.

Production areas

[edit]The principal sources of silver are copper, copper-nickel, gold, lead, and lead-zinc ores obtained from Canada, Mexico,[11] Poland, Peru, Bolivia, Australia[12] and the United States.[13]

Mexico was the world's largest silver producer in 2014, producing 5,000 metric tons (161 million troy ounces), 18.7 percent of the 26,800 tonne (862 million troy ounce) production of the world.[14]

| Mine | Country | 2010 Production |

|---|---|---|

| Cannington Silver/Lead/Zinc Mine | Australia | 38.6 Moz |

| Fresnillo Silver Mine | Mexico | 38.6 Moz |

| San Cristobal Polymetallic Mine | Bolivia | 19.4 Moz |

| Antamina Copper/Zinc Mine | Peru | 14.9 Moz |

| Rudna Copper Mine | Poland | 14.9 Moz |

| Peñasquito Polymetallic Mine | Mexico | 13.9 Moz |

| Project | Country | Anticipated Annual Production Capacity (due within five years) |

|---|---|---|

| Pascua Lama | Chile | 25.0 Moz |

| Navidad | Argentina | 15.0 Moz |

| Juanicipio | Mexico | 14.0 Moz |

| Malku Khota | Bolivia | 13.2 Moz[17] |

| Hackett River | Canada | 13.1 Moz |

| Corani | Peru | 10.0 Moz |

See also

[edit]==

==

References

[edit]==

- ^ King, Hobart, 2013. Silver. Geology.com https://geology.com/minerals/silver.shtml

- ^ Bevan, J., Clark, A., & Symes, R., The Illustrated Encyclopedia of the Mineral Kingdom: Chapter 5: The Mineral Kingdom. Hamlyn, Toronto, 1978. ISBN 0 600 36263 9.

- ^ Dan Oancea: Low Sulphidation Epithermal Vein Deposits http://technology.infomine.com/articles/1/546/silver.sulphidation.epithermal/silver.deposits.–.aspx

- ^ Nicholas A. Robins, Mercury, Mining, and Empire: The Human and Ecological Cost of Colonial Silver Mining in the Andes. Bloomington: Indiana University Press 2011.

- ^ Dan Oancea: Silver Deposits - Carbonate Replacement Deposits http://technology.infomine.com/articles/1/693/silver.deposits.crd/silver.deposits.carbonate.aspx

- ^ a b Kassianidou, V. 2003. Early Extraction of Silver from Complex Polymetallic Ores, in Craddock, P.T. and Lang, J (eds) Mining and Metal production through the Ages. London, British Museum Press: 198–206

- ^ a b Reddy, Rohan, 2019. Silver, Explained. Global X. https://www.globalxetfs.com/silver-explained/#:~:text=Silver%20ore%20is%20mined%20through,the%20ground%20to%20extract%20ore.

- ^ Debnam, Andrew, 2021. Silver. Mindat.org https://www.mindat.org/min-3664.html

- ^ a b c d e Hilliard, Henry E., 2003. "Silver". USGS.

- ^ Greenwood and Earnshaw, 1997. Chemistry of the Elements. Elsevier Ltd. Pg 1178.

- ^ Medical Letter on the CDC & FDA (18 October 2020). "Mexico Silver Mining Is Flourishing with New High Grade Silver Discoveries". Gale Academic: 1991.

- ^ Australia precious metals mining market (gold, silver, diamond) growth and forecasts to 2020. 2014. M2 Presswire, June 26, 2014. ProQuest 1540231009

- ^ United states silver mining market overview and forecast to 2020: Trends, fiscal regime, major projects, and competitive landscape. 2012. M2 Presswire, November 20, 2012. 1171392860

- ^ "pg. 152 – Silver" (PDF). USGS. 2016. Retrieved 29 February 2016.

- ^ CPM Group (2011). The CPM Silver Yearbook 2011. New York, NY: Euromoney Books. p. 68. ISBN 978-0-9826741-4-7.

- ^ CPM Group (2011). The CPM Silver Yearbook 2011. New York, NY: Euromoney Books. p. 74. ISBN 978-0-9826741-4-7.

- ^ "43-101 Preliminary Economic Assessment Technical Report Malku Khota" (PDF). South American Silver Corp. Retrieved July 26, 2011.

==

Peer Review of the above Draft - Dated March 4th, 2021

[edit]This draft is appears to be a complete editing of the original article on ‘Silver mining”

Most noticeably is that the article content has been divided under fewer but larger sections and that Lead section is almost as large as the article itself.

RE: LEAD SECTIONS:

[edit]The first 2 paragraphs appear unchanged. These paragraphs adequately preface the sub-sections that make up the body of the article: they denote the elements and mineral ores where silver is usually found with and these associations necessitates 2 particular extraction methods. In addition to timespan and geography of silver mining.

But 3 new paragraphs have been added to this Lead section. Under the criteria of the lead section as being the most important points of article and to serve as a brief, clean description that will later be expanded on in the article sub-heading, the third, fourth and fifth paragraphs don’t belong in the Lead Section.

RE: NEW LEAD SECTIONS:

[edit]The third and 4th paragraphs are well written but would be better suited to be under a sub-heading like “Silver Ores”. The entire paragraph is well described under this heading with the exception of the sentence: “Floatation separation is a key step in this complicated process”. This sentence would be more suitably found under the existing heading of “Ore Processes”.

The 5th paragraph is a good fit for a new heading such as “Silver Uses and Market”. Given the main article topic is “Silver mining”, the content of this paragraph should not be in the Lead section. It should be moved into its own sub-section. In addition, the sentence in the 2nd paragraph: “ . . . silver is a precious metal . . . .often been lucrative”, is an adequate preface in the Lead section for this paragraph so no change is required to the lead section if this is a sub-section.

RE: REMOVAL OF THE HISTORY SECTION:

[edit]The removal of the History section creates a void. The reader may falsely assume that silver mining is a current-day phenomena. How would the reader know that current ore processing technique are improvements if they don’t know how it began. The design of this new draft can work interimately if there is to be a later intending to move this historically mining section to another Wiki webpage and just link it.

RE: ORE PROCESSING SECTION:

[edit]A very well written, clean and easy to read section. There is no need to give detailed description for the smelting process; mercury amalgamation; the patio process or pan amalgamation as you have wisely already linked these to appropriate Wiki webpages. You may want to also link “Chemical leaching”; as many reader may not be familiar with it.

RE: PRODUCTION AREAS:

[edit]As these tables and content appear to be the same as the original article, this section was not included is Peer review of this draft article.

RE: REFERENCES:

[edit]Only 7 of original citation were maintained and 7 new citations were added. The added citation are reliable sources in that they are well-known and used. However none of these new citations are hyperlink available. There are some sentences lacking citations but this is still a draft.

OVERALL:

[edit]All sections re-written were very well done: simple and clean. There was no bias nor POV issues. The grammar and the spelling were flawless. The Lead section would do better if restored back to the first 2 paragraphs only and the other 3 later Lead sections moved to their own headings. There is a void left by removed the history section that is solved by later editing exercises. Overall a strong draft worthy of publication!

Review by ObliqueFault