User:Sushinut

Current Projects

[edit]none

Resources

[edit]- Tutorial

- How to edit a page

- How to develop articles

- How to create your first article (using the Article Wizard if you wish)

- Manual of Style

- Sign messages on discussion pages using four tildes (~~~~); this will automatically insert username and date.

- The Sandbox

Inline templates

[edit]- {{cite quote}}[This quote needs a citation]: for "actual quotations" which need citations to make them proper

- {{page number}}[page needed]: request a page number for an existing citation

- {{list fact}}

{{list fact}}: request a citation of a source which justifies inclusion of a given entry in a list - {{clarify}}[clarification needed]: request clarification of wording or interpretation

- {{reference necessary}}[citation needed]: wrapper for a portion of a paragraph to highlight it as needing citation

- {{nonspecific}}[not specific enough to verify]: flag a general, yet factual statement as needing to be made more specific before it can be verified

- {{examples}}[example needed]: request examples for clarification

Incomplete citations

[edit]- {{page needed}}[page needed]: in-line request for the page number or page numbers in a work such as journal for an existing citation.

- {{season needed}}[season and episode needed], similar to {{page needed}}: for missing TV season & episode number

- {{volume needed}}[volume & issue needed], similar to {{page needed}}: for missing journal, newspaper, comic, etc., volume and issue numbers)

Verification

[edit]- {{dead link}}[dead link]: request a fix for a dead external link within a paragraph or a reference citation.

- {{failed verification}}[failed verification]: source was checked, and did not contain the cited material

- {{request quotation}}[need quotation to verify]: request a direct quote from an inaccessible source, for verification purposes

- {{self-citation}}[self-published source?]: flag a source that cites the author

- {{verify credibility}}[unreliable source?]: flag a source as possibly being unreliable and/or unverifiable

- {{verify source}}[verification needed]: request that someone verify the cited source backs up the material in the passage

- {{primary source claim}}[non-primary source needed]: flags a statement as only being verified by a Primary source

Content

[edit]- {{dubious}}[dubious – discuss]: flag something as suspected of being incorrect

- {{or}}[original research?]: flag something as possibly containing original research

- {{undue-inline}}[undue weight? – discuss]: show that a statement does not ascribe appropriate weight to its sources, according to their prominence; use in preference to...

- {{POV-statement}}[neutrality is disputed]: dispute the neutrality of a passage

- {{weasel-inline}}[weasel words]: Avoid weasel words

- {{peacock_term}}[peacock prose]: Avoid peacock terms too

- {{jargon-statement}}[jargon]: ...and Jargon

- {{who}}[who?]: for placement after descriptions of a group of persons

- {{whom}}[according to whom?]: placement after mention of a vague third party claim that is not sourced

- {{quantify}}[quantify]: flag a statement as being vague regarding the amount of something

- {{when}}[when?]: flags a particular time period as being vague or ambiguous

- {{timefact}}[chronology citation needed]: request a source confirming or providing the chronology or timeline of a statement

- {{definition}}[when defined as?]: flag a definition as being ambiguous/confusing

Timeliness

[edit]- {{update after}}[needs update]: a template that only shows itself after a specified time, indicating an exceptional statement that will date quickly

Article message box templates

[edit]- {{unreferenced}}, article/section has no sources/references/citations given at all

- {{refimprove}}, article/section has weak or incomplete sources/references/citations

- {{citecheck}}, article/section may have inappropriate or misinterpreted citations

Sandbox for Thermoplastics table

[edit]This article needs additional citations for verification. (October 2009) |

A thermoplastic, also known as thermosoftening plastic,[1] is a polymer that turns to a liquid when heated and freezes to a very glassy state when cooled sufficiently. Most thermoplastics are high-molecular-weight polymers whose chains associate through weak Van der Waals forces (polyethylene); stronger dipole-dipole interactions and hydrogen bonding (nylon); or even stacking of aromatic rings (polystyrene). Thermoplastic polymers differ from thermosetting polymers (Bakelite) as they can, unlike thermosetting polymers, be remelted and remoulded. Many thermoplastic materials are addition polymers; e.g., vinyl chain-growth polymers such as polyethylene and polypropylene.

Theory

[edit]

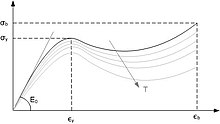

Thermoplastics are elastic and flexible above a glass transition temperature Tg, specific for each one—the midpoint of a temperature range in contrast to the sharp melting point of a pure crystalline substance like water. Below a second, higher melting temperature, Tm, also the midpoint of a range, most thermoplastics have crystalline regions alternating with amorphous regions in which the chains approximate random coils. The amorphous regions contribute elasticity and the crystalline regions contribute strength and rigidity, as is also the case for non-thermoplastic fibrous proteins such as silk. (Elasticity does not mean they are particularly stretchy; e.g., nylon rope and fishing line.) Above Tm all crystalline structure disappears and the chains become randomly inter dispersed. As the temperature increases above Tm, viscosity gradually decreases without any distinct phase change.

Some thermoplastics normally do not crystallize: they are termed "amorphous" plastics and are useful at temperatures below the Tg. They are frequently used in applications where clarity is important. Some typical examples of amorphous thermoplastics are PMMA, PS and PC. Generally, amorphous thermoplastics are less chemically resistant and can be subject to stress cracking. Thermoplastics will crystallize to a certain extent and are called "semi-crystalline" for this reason. Typical semi-crystalline thermoplastics are PE, PP, PBT and PET. The speed and extent to which crystallization can occur depends in part on the flexibility of the polymer chain. Semi-crystalline thermoplastics are more resistant to solvents and other chemicals. If the crystallites are larger than the wavelength of light, the thermoplastic is hazy or opaque. Semi-crystalline thermoplastics become less brittle above Tg. If a plastic with otherwise desirable properties has too high a Tg, it can often be lowered by adding a low-molecular-weight plasticizer to the melt before forming (Plastics extrusion; molding) and cooling. A similar result can sometimes be achieved by adding non-reactive side chains to the monomers before polymerization. Both methods make the polymer chains stand off a bit from one another. Before the introduction of plasticizers, plastic automobile parts often cracked in cold winter weather. Another method of lowering Tg (or raising Tm) is to incorporate the original plastic into a copolymer, as with graft copolymers of polystyrene, or into a composite material. Lowering Tg is not the only way to reduce brittleness. Drawing (and similar processes that stretch or orient the molecules) or increasing the length of the polymer chains also decrease brittleness.

Thermoplastics can go through melting/freezing cycles repeatedly and the fact that they can be reshaped upon reheating gives them their name. This quality makes thermoplastics recyclable. The processes required for recycling vary with the thermoplastic. The plastics used for soda bottles are a common example of thermoplastics that can be and are widely recycled. Animal horn, made of the protein α-keratin, softens on heating, is somewhat reshapable, and may be regarded as a natural, quasi-thermoplastic material.

Although modestly vulcanized natural and synthetic rubbers are stretchy, they are elastomeric thermosets, not thermoplastics. Each has its own Tg, and will crack and shatter when cold enough so that the crosslinked polymer chains can no longer move relative to one another. But they have no Tm and will decompose at high temperatures rather than melt. Recently, thermoplastic elastomers have become available.

Terminology

[edit]The literature on thermoplastics is huge, and can be quite confusing, as the same chemical can be available in many different forms (for example, at different molecular weights), which might have quite different physical properties. The same chemical can be referred to by many different tradenames, by different abbreviations; two chemical compounds can share the same name; a good example of the latter is the word "Teflon" which is used to refer to a specific polymer (PTFE); to related polymers such as PFA, and generically to fluoropolymers.

Furthermore, over the last 30 years, there has been tremendous change in the plastics industry, with many companies going out of business or merging into other companies. Many production plants frequently changed hands or have been relocated to emerging countries in Eastern Europe or Asia, with different trademarks.

Testing

[edit]Testing of thermoplastics can take various forms.

Tensile tests—ISO 527 -1/-2 and ASTM D 638 set out the standardized test methods. These standards are technically equivalent. However they are not fully comparable because of the difference in testing speeds. The modulus determination requires a high accuracy of ± 1 micrometer for the dilatometer.

Flexural tests—3-points flexural tests are among the most common and classic methods for semi rigid and rigid plastics.

Pendulum impact tests—impact tests are used to measure the behavior of materials at higher deformation speeds. Pendulum impact testers are used to determine the energy required to break a standardized specimen by measuring the height to which the pendulum hammer rises after impacting the test piece.

See also

[edit]References

[edit]- ^ http://www.lgschemistry.org.uk/PDF/Thermosoftening_and_thermosetting_plastics.pdf

- ^ a b c d e f g h Polymer Chemistry; The Glass Transition

- ^ International Labour Organisation chemical safety card for polystyrene

- ^ Wilkes, Charles E.; Summers, James W.; Daniels, Charles Anthony; Berard, Mark T. (2005). PVC Handbook. Hanser Verlag. p. 414. ISBN 9781569903797.

Table for Thermoforming

[edit]| Polymer | Forming/process/service Temp |

|---|---|

| Acrylonitrile butadiene styrene (ABS) | 163-177°C[1] or 100-160°C[2] |

| Celluloid | |

| Cellulose acetate | |

| Cycloolefin Copolymer (COC) | |

| Ethylene vinyl acetate (EVA) | |

| Ethylene vinyl alcohol (EVOH) | |

| Fluoroplastics (PTFE, alongside with FEP, PFA, CTFE, ECTFE, ETFE) | |

| Ionomers | |

| Kydex, a trademarked acrylic/PVC alloy | 165-204°C[3] |

| Liquid Crystal Polymer (LCP) | |

| Polyacetal (POM or Acetal) | |

| Polyacrylonitrile (PAN or Acrylonitrile) | |

| Polyamide (PA-6 or Nylon 6) | 220°C[4] or 203-230°C[2] |

| Polyamide (PA-12 or Nylon 12) | 190°C[4] |

| Polyamide-imide (PAI) | |

| Polyaryletherketone (PAEK or Ketone) | |

| Polybutadiene (PBD) | |

| Polybutylene (PB) | |

| Polybutylene terephthalate (PBT) | 190°C[4] |

| Polycaprolactone (PCL) | |

| Polycarbonate (PC) | 180-228°C[2] |

| Polychlorotrifluoroethylene (PCTFE) | |

| Polycyclohexylene dimethylene terephthalate (PCT) | |

| Polyester | |

| Polyetheretherketone (PEEK) | 390°C[4] |

| Polyetherimide (PEI) | 330°[4] |

| Polyetherketoneketone (PEKK) | 340°[4] |

| Polyethersulfone (PES)- see Polysulfone | |

| Polyethylene (PE) | 98-205°C[2] |

| Polyethylene, High Density (HDPE) | 280°C[5] |

| Polyethylene, Low Density (LDPE) | Starts ~60°C[2] |

| Polyethylenechlorinate (PEC) | |

| Polyethylene terephthalate (PET) | |

| Polyethylene terephthalate glycol (PETG) | 80-170°C[2] |

| Polyhydroxyalkanoates (PHAs) | |

| Polyimide (PI) | |

| Polyketone (PK) | |

| Polylactic acid (PLA) | |

| Polymethyl methacrylate, cast (PMMA, Acrylic) | 120-205°C[2] |

| Polymethyl methacrylate, extruded (PMMA, Acrylic) | 120-218°C[2] |

| Polymethylpentene (PMP) | |

| Polyphenylene oxide (PPO) | |

| Polyphenylene sulfide (PPS) | 325°C[4] |

| Polyphthalamide (PPA) | |

| Polypropylene (PP) | 190°C[4] or 154-215°C[2] |

| Polystyrene (PS) | 90-150°C[2] |

| Polystyrene, High Impact (HIPS) | 163-177°C[6] |

| Polysulfone (PSU) | |

| Polytrimethylene terephthalate (PTT) | |

| Polyurethane (PU) | |

| Polyvinyl acetate (PVA, PVAc) | |

| Polyvinyl alcohol (PVOH, PVA, PVAL) | |

| Polyvinyl chloride (PVC) | 90-170°C[2] |

| Polyvinylidene chloride (PVDC) | |

| Styrene-acrylonitrile (SAN) |

test

[edit]Heathen or Heathenry may refer to:

- A pagan

- A modern adherent of Germanic neopaganism.

- An unconverted member of a people or nation that does not acknowledge the God of the Bible[7]

- An uncivilized or irreligious person[7]

- WTVI, Charlotte, North Carolina

- UNC-TV, Research Triangle Park, NC

- Prairie Public Broadcasting, Fargo, North Dakota