User:Project Osprey/sandbox4

History of antioxidants [1]

| Nuclear magnetic resonance (NMR) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Core concepts | |||||||||||||||

|

|||||||||||||||

| By isotope | |||||||||||||||

|

Trixylylphosphate

[edit] | |

| Names | |

|---|---|

Other names

| |

| Identifiers | |

| EC Number |

|

| Properties | |

| C24H27O4P | |

| Molar mass | 410.450 g·mol−1 |

| Appearance | Viscous liquid |

| Density | 1.142 |

| Melting point | −20 °C (−4 °F; 253 K) |

| Boiling point | 394 °C (741 °F; 667 K) |

| 20 µg/L | |

| Hazards | |

| GHS labelling: | |

| |

| Danger | |

| H360F | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Trixylyl phosphate (TXP) is an aromatic phosphate ester historically used as a hydraulic fluid.

Chirality

[edit]| Chemical Chirality | ||||

|---|---|---|---|---|

| An aspect of Stereoisomerism | ||||

| Core concepts | ||||

|

||||

| Assigning and naming | ||||

|

| Rotational axis (Cn) |

Improper rotational elements (Sn) | ||

|---|---|---|---|

| Chiral no Sn |

Achiral mirror plane S1 = σ |

Achiral inversion centre S2 = i | |

| C1 |  |

|

|

| C2 |  |

|

|

Uric

[edit] |

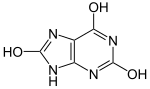

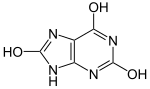

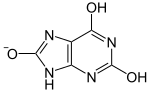

| |

| Lactam form | Lactim form |

|

|

pKa1 |

| |

| Lactam form | Lactim form | Urate ion |

Thermosets example table

[edit]| Name | Properties | Applications |

|---|---|---|

| Example | Example | Example |

| Example | Example | Example |

| Example | Example | Example |

formaldehyde base

- Bakelite, a phenol-formaldehyde

- Urea-formaldehyde

- Melamine resin

- Benzoxazines, formed by the reaction of phenols, formaldehyde and primary amines

- Duroplast

- Diallyl-phthalate (DAP)

- Epoxy resin

- Epoxy novolac resins

- Polyimides and Bismaleimides

- Cyanate esters or polycyanurates

- Furan resins

- Silicone resins

- Thiolyte,

- Vinyl ester resins used for wet lay-up laminating, molding and fast setting industrial protection and repair materials.

- Polyester resin fiberglass systems: sheet molding compounds and bulk molding compounds; filament winding; wet lay-up lamination; repair compounds and protective coatings.

- Polyurethanes: insulating foams, mattresses, coatings, adhesives, car parts, print rollers, shoe soles, flooring, synthetic fibers, etc. Polyurethane polymers are formed by combining two bi- or higher functional monomers/oligomers.

- Polyurea/polyurethane hybrids used for abrasion resistant waterproofing coatings.

- Vulcanized rubber.

- Bakelite, a phenol-formaldehyde resin used in electrical insulators and plasticware.

- Duroplast, light but strong material, similar to Bakelite used for making car parts.

- Urea-formaldehyde foam used in plywood, particleboard and medium-density fiberboard.

- Melamine resin used on worktop surfaces.[1]

- Diallyl-phthalate (DAP) used in high temperature and mil-spec electrical connectors and other components. Usually glass filled.

- Epoxy resin [2] used as the matrix component in many fiber reinforced plastics such as glass-reinforced plastic and graphite-reinforced plastic; casting; electronics encapsulation; construction; protective coatings; adhesives; sealing and joining.

- Epoxy novolac resins used for printed circuit boards, electrical encapsulation, adhesives and coatings for metal.

- Benzoxazines, used alone or hybridised with epoxy and phenolic resins, for structural prepregs, liquid molding and film adhesives for composite construction, bonding and repair.

- Polyimides and Bismaleimides used in printed circuit boards and in body parts of modern aircraft, aerospace composite structures, as a coating material and for glass reinforced pipes.

- Cyanate esters or polycyanurates for electronics applications with need for dielectric properties and high glass temperature requirements in aerospace structural composite components.

- Mold or mold runners (the black plastic part in integrated circuits or semiconductors).

- Furan resins used in the manufacture of sustainable biocomposite construction,[3] cements, adhesives, coatings and casting/foundry resins.

- Silicone resins used for thermoset polymer matrix composites and as ceramic matrix composite precursors.

- Thiolyte, an electrical insulating thermoset phenolic laminate material.

- Vinyl ester resins used for wet lay-up laminating, molding and fast setting industrial protection and repair materials.

table

[edit]

|

Waste composition and recycling by polymer type

[edit]Plastic waste consists of various polymer types, its exact composition will vary, but the estimated global average is shown below.[5][6] Polyolefins make up nearly 50% of all plastic waste and more than 90% of waste is make of thermoset polymers. The amount of each polymer which is recovered for recycling also varies, U.S. data is shown as exemplar.[7]

| Graphs are unavailable due to technical issues. Updates on reimplementing the Graph extension, which will be known as the Chart extension, can be found on Phabricator and on MediaWiki.org. |

| Polymer | Waste production (Mt) | Percentage of all plastic waste | Polymer type | Thermal character |

|---|---|---|---|---|

| High-density polyethylene (HDPE) | 64 | 19.8% | Polyolefin | Thermoplastic |

| Low-density polyethylene (LDPE) | 45 | 13.9% | Polyolefin | Thermoplastic |

| polypropylene (PP) | 62 | 19.1% | Polyolefin | Thermoplastic |

| Polystyrene (PS) | 19 | 5.9% | Aromatic polyolefin | Thermoplastic |

| Polyvinyl chloride (PVC) | 17 | 5.3% | Halogenated | Thermoplastic |

| Polyethylene terephthalate (PET) | 35 | 10.8% | Condensation | Thermoplastic |

| Polyurethane (PUR) | 18 | 5.6% | Condensation | Thermoset[8] |

| PP&A fibers[4] | 51 | 15.7% | Condensation | Thermoplastic |

| All Others | 12 | 3.7% | Various | Varies |

| Total (excludes additives) | 324 | 100% | - | - |

| Polymer | Quantitiy (Thousand tonnes) | Percentage of plastic waste | U.S. recycling rate |

|---|---|---|---|

| High-density polyethylene (HDPE) | 6,300 | 17.7% | 8.9% |

| Low-density polyethylene (LDPE) | 8,590 | 24.1% | 4.3% |

| polypropylene (PP) | 8,150 | 22.8% | 0.6% |

| Polystyrene (PS) | 2,260 | 6.3% | 0.9% |

| Polyvinyl chloride (PVC) | 840 | 2.4% | Negligible |

| Polyethylene terephthalate (PET) | 5,290 | 14.8% | 18.5% |

| All Others | 4,160 | 12% | 26.7% |

| Total | 35,680 | 100% | 8.7% |

| Polymer | Waste production (Mt) | Percentage of all plastic waste | Polymer type | Thermal character | U.S. recycling rate |

|---|---|---|---|---|---|

| High-density polyethylene (HDPE) | 64 | 19.8% | Polyolefin | Thermoplastic | 8.9% |

| Low-density polyethylene (LDPE) | 45 | 13.9% | Polyolefin | Thermoplastic | 4.3% |

| polypropylene (PP) | 62 | 19.1% | Polyolefin | Thermoplastic | 0.6% |

| Polystyrene (PS) | 19 | 5.9% | Aromatic polyolefin | Thermoplastic | 0.9% |

| Polyvinyl chloride (PVC) | 17 | 5.3% | Halogenated | Thermoplastic | Negligible |

| Polyethylene terephthalate (PET) | 35 | 10.8% | Condensation | Thermoplastic | 18.5% |

| Polyurethane (PUR) | 18 | 5.6% | Condensation | Thermoset[9] | No data |

| PP&A fibers[4] | 51 | 15.7% | Condensation | Thermoplastic | Negligible |

| All Others | 12 | 3.7% | Various | Varies | Varies |

| Total (excludes additives) | 324 | 100% | - | - |

Recycling of polymer types

[edit]| Polymer | Quantitiy (Thousand tonnes) | Percentage of plastic waste | U.S. recycling rate |

|---|---|---|---|

| High-density polyethylene (HDPE) | 6,300 | 17.7% | 8.9% |

| Low-density polyethylene (LDPE) | 8,590 | 24.1% | 4.3% |

| polypropylene (PP) | 8,150 | 22.8% | 0.6% |

| Polystyrene (PS) | 2,260 | 6.3% | 0.9% |

| Polyvinyl chloride (PVC) | 840 | 2.4% | Negligible |

| Polyethylene terephthalate (PET) | 5,290 | 14.8% | 18.5% |

| All Others | 4,160 | 12% | 26.7% |

| Total | 35,680 | 100% | 8.7% |

All common plastics can be recycled, but actual rates of recycling vary significantly between polymers. The physical properties of the plastics and the amount of additives they contain largely control this. Foamed plastics such as polystyrene or polyurethane is usually uneconomical to collect (a truck-full of foam contains little actual plastic) and what little recycling does take place is mostly recovered industrial scrap. Soft plastics, particularly in the form of films and foils are difficult to flake or gravity sort and tend to clog equipment

This is driven by a mixture of economics and technical limitations

PET 725 cheapest HDPE 815 LDPE 100 PP 945

Widely recycled

[edit]Sometimes recycled

[edit]Usually not recycled

[edit]Production

[edit]Polyurethanes are produced by mixing two or more liquid streams. The polyol stream contains catalysts, surfactants, blowing agents (when making polyurethane foam insulation) and so on. The two components are referred to as a polyurethane system, or simply a system. The isocyanate is commonly referred to in North America as the 'A-side' or just the 'iso'. The blend of polyols and other additives is commonly referred to as the 'B-side' or as the 'poly'.[citation needed] This mixture might also be called a 'resin' or 'resin blend'. In Europe the meanings for 'A-side' and 'B-side' are reversed.[citation needed] Resin blend additives may include chain extenders, cross linkers, surfactants, flame retardants, blowing agents, pigments, and fillers. Polyurethane can be made in a variety of densities and hardnesses by varying the isocyanate, polyol or additives.

Manufacturing

[edit]The methods of manufacturing polyurethane finished goods range from small, hand pour piece-part operations to large, high-volume bunstock and boardstock production lines. Regardless of the end-product, the manufacturing principle is the same: to meter the liquid isocyanate and resin blend at a specified stoichiometric ratio, mix them together until a homogeneous blend is obtained, dispense the reacting liquid into a mold or on to a surface, wait until it cures, then demold the finished part.

Dispensing equipment

[edit]Although the capital outlay can be high, it is desirable to use a meter-mix or dispense unit for even low-volume production operations that require a steady output of finished parts. Dispense equipment consists of material holding (day) tanks, metering pumps, a mix head, and a control unit. Often, a conditioning or heater–chiller unit is added to control material temperature in order to improve mix efficiency, cure rate, and to reduce process variability. Choice of dispense equipment components depends on shot size, throughput, material characteristics such as viscosity and filler content, and process control. Material day tanks may be single to hundreds of gallons in size and may be supplied directly from drums, IBCs (intermediate bulk containers, such as totes), or bulk storage tanks. They may incorporate level sensors, conditioning jackets, and mixers. Pumps can be sized to meter in single grams per second up to hundreds of pounds per minute. They can be rotary, gear, or piston pumps, or can be specially hardened lance pumps to meter liquids containing highly abrasive fillers such as chopped or hammer-milled glass fiber and wollastonite. [citation needed]

-

A high-pressure polyurethane dispense unit, showing control panel, high-pressure pump, integral day tanks, and hydraulic drive unit

-

A high-pressure mix head, showing simple controls (front view)

-

A high-pressure mix head, showing material supply and hydraulic actuator lines (rear view)

The pumps can drive low-pressure (10 to 30 bar, 1 to 3 MPa) or high-pressure (125 to 250 bar, 12.5 to 25.0 MPa) dispense systems. Mix heads can be simple static mix tubes, rotary-element mixers, low-pressure dynamic mixers, or high-pressure hydraulically actuated direct impingement mixers. Control units may have basic on/off and dispense/stop switches, and analogue pressure and temperature gauges, or may be computer-controlled with flow meters to electronically calibrate mix ratio, digital temperature and level sensors, and a full suite of statistical process control software. Add-ons to dispense equipment include nucleation or gas injection units, and third or fourth stream capability for adding pigments or metering in supplemental additive packages.

-

A low-pressure mix head with calibration chamber installed, showing material supply and air actuator lines

-

Low-pressure mix head components, including mix chambers, conical mixers, and mounting plates

-

5-gallon (20-liter) material day tanks for supplying a low-pressure dispense unit

Tooling

[edit]Distinct from pour-in-place, bun and boardstock, and coating applications, the production of piece parts requires tooling to contain and form the reacting liquid. The choice of mold-making material is dependent on the expected number of uses to end-of-life (EOL), molding pressure, flexibility, and heat transfer characteristics.

RTV silicone is used for tooling that has an EOL in the thousands of parts. It is typically used for molding rigid foam parts, where the ability to stretch and peel the mold around undercuts is needed. The heat transfer characteristic of RTV silicone tooling is poor. High-performance, flexible polyurethane elastomers are also used in this way.

Epoxy, metal-filled epoxy, and metal-coated epoxy is used for tooling that has an EOL in the tens of thousands of parts. It is typically used for molding flexible foam cushions and seating, integral skin and microcellular foam padding, and shallow-draft RIM bezels and fascia. The heat transfer characteristic of epoxy tooling is fair; the heat transfer characteristic of metal-filled and metal-coated epoxy is good. Copper tubing can be incorporated into the body of the tool, allowing hot water to circulate and heat the mold surface.

Aluminum is used for tooling that has an EOL in the hundreds of thousands of parts. It is typically used for molding microcellular foam gasketing and cast elastomer parts, and is milled or extruded into shape.

Mirror-finish stainless steel is used for tooling that imparts a glossy appearance to the finished part. The heat transfer characteristic of metal tooling is excellent.

Finally, molded or milled polypropylene is used to create low-volume tooling for molded gasket applications. Instead of many expensive metal molds, low-cost plastic tooling can be formed from a single metal master, which also allows greater design flexibility. The heat transfer characteristic of polypropylene tooling is poor, which must be taken into consideration during the formulation process.

bits

[edit]Moisture cure polyurethane Polyurethane dispersion Polyurethane urea elastomer

- ^ Roberto C. Dante, Diego A. Santamaría and Jesús Martín Gil (2009). "Crosslinking and thermal stability of thermosets based on novolak and melamine". Journal of Applied Polymer Science. 114 (6): 4059–4065. doi:10.1002/app.31114.

- ^ Enrique Guzman; Joël Cugnoni; Thomas Gmür (2014). "Multi-factorial models of a carbon fibre/epoxy composite subjected to accelerated environmental ageing". Composite Structures. 111 (4): 179–192. doi:10.1016/j.compstruct.2013.12.028.

- ^ T Malaba, J Wang, Journal of Composites, vol. 2015, Article ID 707151, 8 pages, 2015. doi:10.1155/2015/707151

- ^ a b c PP&A stand for polyester, polyamide and acrylate polymers; all of which are used to make synthetic fibres. Care should be taken not to confuse it with polyphthalamide (PPA)

- ^ a b c d Cite error: The named reference

Geyer2017was invoked but never defined (see the help page). - ^ a b c Geyer, Roland (2020). Plastic waste and recycling : environmental impact, societal issues, prevention, and solutions. Amsterdam: Academic Press. p. 22. ISBN 978-0-12-817880-5.

- ^ a b c ""Advancing Sustainable Materials Management: 2018 Tables and Figures" (PDF). U.S. EPA.

- ^ The majority of polyurethanes are thermosets, however some thermoplastics are also produced, for instance spandex

- ^ The majority of polyurethanes are thermosets, however some thermoplastics are also produced, for instance spandex

- ^ "Plastic Recycling Factsheet" (PDF). EuRIC - European Recycling Industries’ Confederation. Retrieved 9 November 2021.