User:NKrop/sandbox

Appearance

Equations

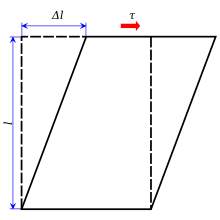

[edit]- For average shear stress

- where

- is the average shear stress,

- is the shear force applied to each section of the part, and

- is the area of the section.[1]

- Average shear stress can also be defined as the total force of as

- [2]

- Practically, the equations only give an approximation. Stress is not often equally distributed across a part so the shear strength would need to be higher to count for the estimate along with a factor of safety.

Comparisons

[edit]There are no published standard values for shear strength like with tensile and yield strength. Instead, it is common for it to be estimated as 60% of the ultimate tensile strength. Shear strength can be measures by a torsion test where it is equal to there torsional strength.[3][4]

- ^ Hibbeler, Russell. Mechanics of materials. ISBN 1-292-17828-0. OCLC 1014358513.

- ^ "Mechanics eBook: Shear and Bearing Stress". www.ecourses.ou.edu. Retrieved 2020-02-14.

- ^ "Shear Strength - Instron". www.instron.us. Retrieved 2020-02-14.

- ^ Portl; Portl, bolt com; Bolt; Company, Manufacturing; St, Inc 3441 NW Guam; Portl; PT547-6758, OR 97210 USA Hours: Monday-Friday 6 AM to 5 PM. "Calculating Yield & Tensile Strength". Portland Bolt. Retrieved 2020-02-14.

{{cite web}}:|last4=has generic name (help)CS1 maint: numeric names: authors list (link)