Thermoplastic: Difference between revisions

→Theory: removed PVC Tm; incorrect |

|||

| Line 121: | Line 121: | ||

| [[Polyvinyl alcohol]] (PVOH, PVA, PVAL)||||<ref name="Polymer Chemistry"/>85 °C |

| [[Polyvinyl alcohol]] (PVOH, PVA, PVAL)||||<ref name="Polymer Chemistry"/>85 °C |

||

|- |

|- |

||

| [[Polyvinyl chloride]] (PVC)||||<ref name="Polymer Chemistry"/>81 °C |

|||

| [[Polyvinyl chloride]] (PVC)||<ref name="pvc handbook">{{Cite book|last = Wilkes|first = Charles E.|last2 = Summers|first2 = James W.|last3 = Daniels|first3 = Charles Anthony|last4 = Berard|first4 = Mark T.|title = PVC Handbook|publisher = Hanser Verlag|year = 2005|page=414|url = http://books.google.com/books?id=YUkJNI9QYsUC&pg=PA414|isbn = 9781569903797}}</ref>100–260 °C||<ref name="Polymer Chemistry"/>81 °C |

|||

|- |

|- |

||

| [[Polyvinylidene chloride]] (PVDC)||185 °C||40 °C |

| [[Polyvinylidene chloride]] (PVDC)||185 °C||40 °C |

||

Revision as of 21:37, 25 January 2010

Theory

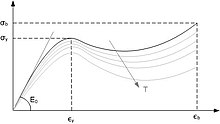

Thermoplastics are elastic and flexible above a glass transition temperature Tg, specific for each one—the midpoint of a temperature range in contrast to the sharp melting point of a pure crystalline substance like water. Below a second, higher melting temperature, Tm, also the midpoint of a range, most thermoplastics have crystalline regions alternating with amorphous regions in which the chains approximate random coils. The amorphous regions contribute elasticity and the crystalline regions contribute strength and rigidity, as is also the case for non-thermoplastic fibrous proteins such as silk. (Elasticity does not mean they are particularly stretchy; e.g., nylon rope and fishing line.) Above Tm all crystalline structure disappears and the chains become randomly inter dispersed. As the temperature increases above Tm, viscosity gradually decreases without any distinct phase change.

Some thermoplastics normally do not crystallize: they are termed "amorphous" plastics and are useful at temperatures below the Tg. They are frequently used in applications where clarity is important. Some typical examples of amorphous thermoplastics are PMMA, PS and PC. Generally, amorphous thermoplastics are less chemically resistant and can be subject to stress cracking. Thermoplastics will crystallize to a certain extent and are called "semi-crystalline" for this reason. Typical semi-crystalline thermoplastics are PE, PP, PBT and PET. The speed and extent to which crystallization can occur depends in part on the flexibility of the polymer chain. Semi-crystalline thermoplastics are more resistant to solvents and other chemicals. If the crystallites are larger than the wavelength of light, the thermoplastic is hazy or opaque. Semi-crystalline thermoplastics become less brittle above Tg. If a plastic with otherwise desirable properties has too high a Tg, it can often be lowered by adding a low-molecular-weight plasticizer to the melt before forming (Plastics extrusion; molding) and cooling. A similar result can sometimes be achieved by adding non-reactive side chains to the monomers before polymerization. Both methods make the polymer chains stand off a bit from one another. Before the introduction of plasticizers, plastic automobile parts often cracked in cold winter weather. Another method of lowering Tg (or raising Tm) is to incorporate the original plastic into a copolymer, as with graft copolymers of polystyrene, or into a composite material. Lowering Tg is not the only way to reduce brittleness. Drawing (and similar processes that stretch or orient the molecules) or increasing the length of the polymer chains also decrease brittleness.

Thermoplastics can go through melting/freezing cycles repeatedly and the fact that they can be reshaped upon reheating gives them their name. This quality makes thermoplastics recyclable. The processes required for recycling vary with the thermoplastic. The plastics used for soda bottles are a common example of thermoplastics that can be and are widely recycled. Animal horn, made of the protein α-keratin, softens on heating, is somewhat reshapable, and may be regarded as a natural, quasi-thermoplastic material.

Although modestly vulcanized natural and synthetic rubbers are stretchy, they are elastomeric thermosets, not thermoplastics. Each has its own Tg, and will crack and shatter when cold enough so that the crosslinked polymer chains can no longer move relative to one another. But they have no Tm and will decompose at high temperatures rather than melt. Recently, thermoplastic elastomers have become available.