Rotating pocket heater

A rotating pocket heater, also called pocket heater or Kinder heater, holds and rotates a substrate during vacuum deposition.[1] During rotation, the substrate is sequentially exposed to more than one environment, for example, heat, oxygen, metal vapor, etc.[2] Rotating pocket heaters has been used in reactive evaporation system to create YBa2Cu3O7 layers on planar semiconductor wafers.[3]

Magnesium diboride

[edit]

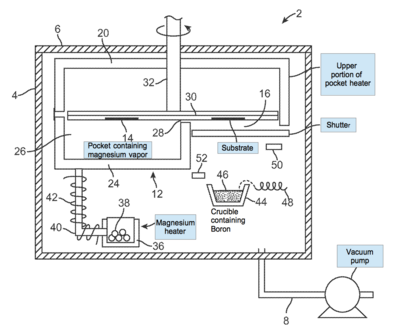

The illustration on the right shows an example of a pocket heater being used to deposit a layers of magnesium diboride on a substrate. A vertical shaft (32) turns a horizontal disk (30) several hundred rotations per minute (RPM). The illustration shows two of several substrates (14) attached to the underside of the rotating disk. The substrates are attached at their edges, so that most of the undersides of the substrates are exposed to the vapor below. The entire apparatus is enclosed in a chamber kept at low pressure by a vacuum pump.

Magnesium diboride (MgB2) is an ionic solid with superconducting properties. Vapor deposition is difficult, because the vapor pressure of magnesium is much higher than boron. The pocket heater solves this problem by providing a separate environment for each material.

Spying charge

[edit]In May 2015, FBI agents arrested Professor Xiaoxing Xi, chairman of Temple University's physics department, accusing him of sharing schematics of a pocket heater with Chinese scientists. The prosecutors dropped all charges in September 2015 after it was shown that they had misconstrued the evidence and Xi has never shared the diagram of the pocket heater with anyone in China.[4] Rotating pocket heater is not a restricted technology and was first invented by German physicists Berberich, Prusseit, and Kinder. [2] Theva Dunnschichttechnik GmbH of Germany holds the patent for pocket heater.

References

[edit]- ^ Moeckly, B H; Ruby, W S (2006). "Growth of high-quality large-area MgB2 thin films by reactive evaporation". Superconductor Science and Technology. 19 (6): L21 – L24. arXiv:cond-mat/0601669. Bibcode:2006SuScT..19L..21M. doi:10.1088/0953-2048/19/6/L02. ISSN 0953-2048. S2CID 119438110.

- ^ a b Berberich, P.; Utz, B.; Prusseit, W.; Kinder, H. (1994). "Homogeneous high quality YBa2Cu3O7 films on 3" and 4" substrates". Physica C: Superconductivity. 219 (3–4): 497–504. Bibcode:1994PhyC..219..497B. doi:10.1016/0921-4534(94)90405-7. ISSN 0921-4534.

- ^ Pavuna, Davor; Matijasevic, Vladimir C.; Slycke, Per; Bozovic, Ivan (1998). "Reactive evaporation technology for fabrication of YBCO wafers for microwave applications". In Pavuna, Davor; Bozovic, Ivan (eds.). Superconducting and Related Oxides: Physics and Nanoengineering III. Vol. 3481. pp. 190–196. doi:10.1117/12.335875. ISSN 0277-786X. S2CID 109520749.

{{cite book}}:|journal=ignored (help) - ^ Matt Apuzzo (11 September 2015). "U.S. Drops Charges That Professor Shared Technology With China". The New York Times.