Autotransformer: Difference between revisions

m Reverting possible vandalism by 78.144.77.173 to version by 59.91.200.44. False positive? Report it. Thanks, ClueBot. (664517) (Bot) |

|||

| Line 16: | Line 16: | ||

Like multiple-winding [[transformer]]s, autotransformers operate on time-varying [[magnetic field]]s and so cannot be used directly on DC. |

Like multiple-winding [[transformer]]s, autotransformers operate on time-varying [[magnetic field]]s and so cannot be used directly on DC. |

||

i work like this machines i keep on pumping the dirty dog next door |

|||

== Applications == |

== Applications == |

||

Revision as of 11:59, 9 April 2009

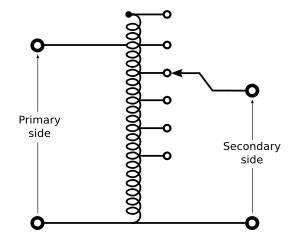

An autotransformer (sometimes called autoformer)[1] is an electrical transformer with only one winding. The winding has at least three electrical connection points called taps. The voltage source and the load are each connected to two taps. One tap at the end of the winding is a common connection to both circuits (source and load). Each tap corresponds to a different source or load voltage. In an autotransformer a portion of the same winding acts as part of both the primary and secondary winding.

Operation

The ratio of secondary to primary voltages is equal to the ratio of the number of turns of the winding they connect to. For example, connecting at the middle and bottom of the autotransformer will half the voltage. Depending on the application, that portion of the winding used solely in the higher-voltage (lower current) portion may be wound with wire of a smaller gauge, though the entire winding is directly connected.

Limitations

A failure of the insulation or the windings of an autotransformer can result in full input voltage applied to the output. This is an important safety consideration when deciding to use an autotransfomer in a given application.

Because it requires both fewer windings and a smaller core, an autotransformer for power applications is typically lighter and less costly than a two-winding transformer, up to a voltage ratio of about 3:1 - beyond that range a two-winding transformer is usually more economical.

In three phase power transmission applications, autotransformers have the limitations of not suppressing harmonic currents and as acting as another source of ground fault currents. A large three-phase autotransformer may have a "buried" delta winding, not connected to the outside of the tank, to absorb some harmonic currents.

A special form of autotransformer called a "zig zag" is used to provide grounding (earthing) on three-phase systems that otherwise have no connection to ground (earth). A zig-zag transformer a path for current that is common to all three phases (so-called "zero sequence" current).

Like multiple-winding transformers, autotransformers operate on time-varying magnetic fields and so cannot be used directly on DC.

i work like this machines i keep on pumping the dirty dog next door

Applications

Autotransformers are frequently used in power applications to interconnect systems operating at different voltage classes, for example 138 kV to 66 kV for transmission. Another application is in industry to adapt machinery built (for example) for 480 V supplies to operate on a 600 V supply. They are also often used for providing conversions between the two common domestic mains voltage bands in the world (100-130 and 200-250). The links between the UK 400kV and 275kV 'SuperGrid' networks are normally three phase autotransformers with taps at the common neutral end.

On long rural power distribution lines, special autotransformers with automatic tap-changing equipment are inserted as voltage regulators, so that customers at the far end of the line receive the same average voltage as those closer to the source. The variable ratio of the autotransformer compensates for the voltage drop along the line.

In audio applications, tapped autotransformers are used to adapt speakers to constant-voltage audio distribution systems, and for impedance matching such as between a low-impedance microphone and a high-impedance amplifier input.

In UK railway applications, it is common to power the trains at 25kV AC. To increase the distance between electricity supply Grid feeder points they can be arranged to supply a 25-0-25 kV supply with the third wire (opposite phase) out of reach of the train's overhead collector pantograph. The 0V point of the supply is connected to the rail while one 25kV point is connected to the overhead contact wire. At frequent (about 10km) intervals an autotransformer links the contact wire to rail and to the second (antiphase) supply conductor. This system increases usable transmission distance, reduces induced interference into external equipment and reduces cost. A variant is occasionally seen where the supply conductor is at a different voltage to the contact wire with the autotransformer ratio modified to suit.

References - "Fahrleitungen electrischer Bahnen" BG Teubner-Verlag, Stuttgart, page 672. An English edition "Contact Lines for Electric Railways" appears to be out of print. This industry standard text describes the various European electrification principles. See the website of the UIC in Paris for the relevant international rail standards, in English. No comparable publications seem to exist for American railways, probably due to the paucity of electrified installations there.

Variable autotransformers

As with two-winding transformers, autotransformers may be equipped with many taps and automatic switchgear to allow them to act as automatic voltage regulators, to maintain a steady voltage at the customers' service during a wide range of load conditions.

By exposing part of the winding coils and making the secondary connection through a sliding brush, an almost continuously variable turns ratio can be obtained, allowing for very smooth control of voltage. Applicable only for relatively low voltage designs, this device is known as a variable AC transformer, or commonly by the trade name of Variac.

From 1934 to 2002, Variac was a U.S. trademark of General Radio for a variable autotransformer intended to conveniently vary the output voltage for a steady AC input voltage. In 2004, Instrument Service Equipment applied for the Variac trademark for the same type of product. The term has acquired the status of a genericized trademark and is often used to describe similar variable autotransformers made by other makers.

References

- Terrell Croft and Wilford Summers (ed), American Electricians' Handbook, Eleventh Edition, McGraw Hill, New York (1987) ISBN 0-07013932-6

- Donald G. Fink and H. Wayne Beaty, Standard Handbook for Electrical Engineers, Eleventh Edition,McGraw-Hill, New York, 1978, ISBN 0-07020974-X

- ^ Paul Horowitz and Winfield Hill, The Art of Electronics Second Edition, Cambridge University Press, Cambridge MA, 1989, ISBN 0-521-37095-7, page 58